|

FULL STORY

.

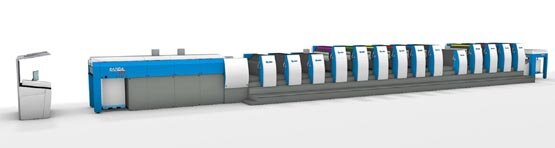

The new Rapida 106 will feature four printing units, dryer, perfecting, six further printing units, drying, coating and perforating units as well as a triple delivery extension with VariDryBLUE drying technology

The Appl Group in Wemding, Germany, recently ordered a highly automated KBA Rapida 106 with a total of 14 printing and finishing units. The almost 30m-long press will be delivered in April next year.

The new Rapida 106 will significantly improve the production of high-quality finished covers for magazines, catalogues and books at aprinta in terms of efficiency. This new medium-format press will have an output of up to 18,000sph. It will be equipped with four inking units, a dryer, perfecting, six further inking units, each with a dryer, perforating and a coating unit as well as a triple delivery extension. DriveTronic SPC direct-drive technology for automatic plate changing, CleanTronic washing systems and inline density control with QualiTronic ColorControl all play a key role in optimising makeready times, saving waste and improving print quality. All of these features make the Rapida 106 the most cutting-edge perfector to be installed in Europe.

The entire Rapida 106 is set up for UV production and features HR-UV drying modules. As a purely UV press time-consuming ink range changes will be prevented in the future. Further benefits of the HR-UV system mean that the sheets can be sent straight to post-press and energy consumption is considerably reduced compared to conventional UV systems. A second coating feed system as well as automatic anilox roller changes with AniloxLoader ensure that both coaters can handle various types of coating as well the quick change between water-based and UV coating systems. VariDryBLUE drying technology in the extended delivery, energy-efficient multi-purpose cooling units and VISUenergy real-time energy monitoring all make this press especially environmentally friendly and energy efficient.

The Appl Group remains a pure KBA user in sheetfed offset with this new investment. The Group operates ten Rapida machines, six of which are large-format and four are medium-format, totalling nearly 80 printing and finishing units.

© Graphic Repro On-line, 24 October 2014.

|