|

|

| Issue: Graphic Repro On-line features 2014+2015 |

Chapter: 07 On-line features for Sep/Oct (more below)

|

|

|

|

|

|

|

World premiere of a new generation of digital machines for label printing - the Gallus DCS 340 Digital Converting System impresses with 1200dpi

|

|

Gallus Innovation Days' Premiere of new Digital Label Press

|

During the Gallus Innovation Days 2014, taking place from 23 - 25 September in St Gallen, Switzerland, Gallus unveiled its future machine generation for digital label printing.

For its world premiere, a pre-series model of the digital printing system was presented to the industry for the first time. Gallus DCS 340 (Digital Converting System) is the designation of the new digital inline label printing system, which has been developed in co-operation with Heidelberger Druckmaschinen AG and Fujifilm and will set new standards in digital label production.

The market is changing

Due to continuing growth in short-run label production and personalised, versioned labels, we are seeing investment on the market steadily shift towards printing presses that utilise digital printing. The growth potential for this printing method is considerable and we expect to see high growth rates over the next ten years, said Stefan Heiniger, COO Label Business at Gallus Ferd. Rüesch AG.

World premiere: Stefan Heiniger, COO World premiere: Stefan Heiniger, COO

of the Labels division at Gallus, Heidelberg CEO Gerold Linzbach and anchor investor Ferdinand Rüesch, start up the new digital printing system for label printing, the Gallus DCS 340.

Despite this, many label printers have not yet taken the decision to introduce digital printing - in part due to the compromises that are associated with this process in label printing. Slow printing speeds, the inability to print some spot colours, inadequate workflow solutions and a lack of true inline finishing and embellishment capabilities can result in additional process steps or undesirable compromises when it comes to label features. What's more, current digital printing press solutions often result in less efficient production and poor compatibility with additional printing and embellishment processes.

The next generation sets new standards in printing and register quality

Thanks to the collaboration with Heidelberg and its partner for inkjet technology, Fujifilm, the new Gallus DCS 340 digital inline label printing system features a printing module with next-generation inkjet printing heads. The unique print head design enables several heads to be joined together for a greater print width, without visible transitions.

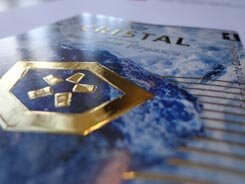

The new Gallus DCS 340 digital converting system prints in a resolution The new Gallus DCS 340 digital converting system prints in a resolution

of 1200dpi.

A native resolution of 1200 dpi delivers print quality that is unmatched in UV inkjet printing today. This technology - combined with the speed of flexographic printing and the efficiency of digital printing - results in the new Gallus DCS 340 digital press, and of course Gallus

is also staying true to its high standards in register accuracy on this new digital machine.

Process flexibility and productivity on a whole new level

Digital technology makes it easier to handle variable data and versioning when producing labels and thus supports the cost-effective production of short runs. This gives label printers the flexibility that their customers expect from them. By combining the strengths of digital printing with an inline finishing process that has been specially optimised for digital printing, the Gallus DCS 340 gives users the chance to varnish, embellish and further process labels inline - from the roll to the finished die-cut label in a single production operation.

Automated prepress workflow

The standardised, user-friendly interface of the Gallus DCS 340 makes sure that label printers benefit from the speed, quality and consistency they need in digital printing. The standardised, user-friendly interface of the Gallus DCS 340 makes sure that label printers benefit from the speed, quality and consistency they need in digital printing.

Soon to become a reality: Label printing on the new Gallus DCS 340 digital printing press sets new standards.

The Heidelberg Prinect Digital Front End is used to automate the prepress workflow and thus ensure data is prepared efficiently, complete with comprehensive colour management. The printer also benefits from functions such as spot colour matching, the PDF Toolbox and Prepress Manager for even greater efficiency.

A perfect combination of digital printing technology and conventional further processing

Digital printing offers benefits in terms of reducing order-related fixed costs and costs for versioning and personalisation, while the conventional printing functions in this machine system open up additional embellishment options and enable inline finishing such as coating and die cutting. With seamless integration of conventional and digital processing steps, data preparation is a simple and efficient process. The Gallus DCS 340 has been developed jointly with Heidelberg and Fujifilm to meet the requirements of the future and offers label printers the ultimate in quality, productivity and flexibility. Thanks to the Gallus DCS 340, label printers will be able to enjoy the benefits of efficient digital production and a full range of functions, even when handling short runs and personalised jobs - just as they have come to expect from Gallus machine systems, said Heiniger.

Gallus ECS 340: A Gallus best seller with a new direct matrix stripper

The new, innovative functionality of the high-performance matrix stripper on the Gallus ECS 340 represents a masterpiece of mechatronics by Gallus development engineers. To date, the direct matrix-stripping systems on the market have already brought a number of advantages over standard matrix strippers.

The Gallus ECS 340 with further enhanced productivity and the new high-performance matrix stripper can execute complex die-cutting contours even at high production speeds. The Gallus ECS 340 with further enhanced productivity and the new high-performance matrix stripper can execute complex die-cutting contours even at high production speeds.

Using a path roller to guide and support the matrix over just a short distance results in far fewer matrix tears and thus delivers greater process reliability. Complex die-cutting formes - with recessed edges, for example - remain problematic, however. The new Gallus high-performance matrix stripper was developed specifically for matrix removal with highly complex die lines at maximum speeds and enables a stable matrix removal process at all times. The test and development engineers at Gallus have taken a close look at the matrix-removal process and improved its functionality, its stability and thus its productivity with a new type of matrix stripper.

The new Gallus RCS 430: A benchmark for professional label printing

For the first time ever, visitors to the Gallus Innovation Days will be offered a unique insight into ongoing development work. The Looking over the developers' shoulders part of the programme will provide a one-off opportunity to get an idea of what the new Gallus RCS 430 - the new benchmark in narrow-web label printing - is going to be like. For the first time since its market launch, the Gallus RCS is being completely revamped. The machine system is being equipped with a state-of-the-art control platform so as to be ready for future market requirements and advances in technology. This control platform is already in use in the Gallus ECS 340 and Gallus EM S machine systems, and promises printers potential synergies in terms of providing a standardised technology platform for a range of machine systems.

.

The success of the Gallus RCS is based on its unique combination of modular design, outstanding process flexibility and high level of automation.

Reduced complexity is a further advantage. Having a common control platform simplifies the training of press operators and means staff can easily be assigned to different machine systems as they are already familiar with the user interface. Many of the spare parts for different machine types are also the same, which makes servicing work more straightforward. Furthermore, various technical adjustments have been made to the hardware based on Gallus RCS users' feedback and experiences. Examples include improvements to web transport, a higher register accuracy and optimised inking units in the offset printing unit, which exhibit enhanced colour stability.

Innovative screen printing: Gallus Screeny A-Line - A stands for advanced

Close-up of the Gallus Screeny A-Line. Close-up of the Gallus Screeny A-Line.

The main feature of the new A-Line is its exceptional robustness, which is particularly advantageous when handling screen printing plates both inside and outside the press. The Gallus Screeny A-Line is therefore ideal for maximising the number of times plates can be re-used. This higher re-utilisation rate is also the quickest way to significantly cut costs per screen-printed label. However, robustness is just one of the requirements a good screen printing plate needs to satisfy. Excellent print results, optimum image resolution, a wide range of possible applications, a perfect ink flow and straightforward final checking of the imaged screen printing plate are further factors that have been taken into account during the development process of the Gallus Screeny A-Line. All this makes the Gallus Screeny A-Line the best and most cutting-edge screen printing plate that Gallus currently supplies to the market.

Metallic doming - the unique metal relief effect

Metallic doming is a unique combination printing process in narrow-web label printing. The first step is to apply the print image using rotary screen printing. A metal foil is then laminated onto the screen print. Metallic doming is a unique combination printing process in narrow-web label printing. The first step is to apply the print image using rotary screen printing. A metal foil is then laminated onto the screen print.

Relief effect of metallic doming for solid areas and lines.

At the Gallus Innovation Days, this new combination printing process will be demonstrated live to label printers for the first time on the Gallus RCS 330. The special feature of metallic doming is that it enables users to apply a metal relief effect on transparent self-adhesive materials or tube laminate. An embellishing effect of this kind on monomaterial or clear material is a true innovation. Naturally, metallic doming can also be applied to all standard self-adhesive paper substrates.

Gallus Customer Services offers new consumables

Twinlock coating and new doctor blade:

The revolutionary full-area and thus seamless self-adhesive Twinlock printing cylinder coating solves virtually all the problems associated with applying the flexographic printing plate to the printing cylinder, because it dispenses entirely with the need for flexographic adhesive tapes and all the associated drawbacks. The new Twinlock coating is available in various thicknesses on both synthetic sleeves and aluminium cylinders.

New to the Gallus range of accessories - Twinlock-coated printing cylinders. New to the Gallus range of accessories - Twinlock-coated printing cylinders.

Gallus now offers three different high-quality doctor blade types for all Gallus presses. They are supplied in a practical cardboard dispenser box and are already cut to exactly the right final dimension of the relevant press. The new Gallus doctor blades are available in three different qualities.

More about Gallus can be found at: www.gallus-group.com.

© Graphic Repro On-line, 24 September 2014.

|

|

|