|

|

| Issue: Graphic Repro On-line features 2014+2015 |

Chapter: 07 On-line features for Sep/Oct (more below)

|

|

|

|

|

|

|

French commercial print shop offers its customers optimum service with new offset and new Linoprint C 751 digital press from Heidelberg, on back of postpress buys

|

|

France's first Speedmaster XL 106: eight-colour perfector

|

JF Impression uses France's first Speedmaster XL 106 perfecting press with an output of 18,000 sheets per hour

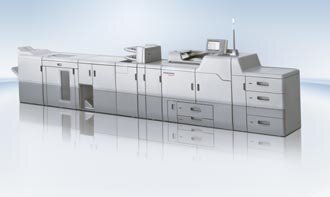

Linoprint C 751 produces backstitched brochures in very short runs with special finishing module

For Montpellier-based print shop JF Impression, 2014 once again represents a major technological leap with the purchase of several large presses. Jacques Fabrégat, owner and Managing Director of the company, has opted for reliable and high-performance presses that enable him to offer his customers the best possible service and to ensure success for his print shop.

JF Impression uses France's first eight-colour Speedmaster XL 106 perfecting press with 18,000 sheets/hour option JF Impression uses France's first eight-colour Speedmaster XL 106 perfecting press with 18,000 sheets/hour option

He was the first in France to purchase an eight-colour Speedmaster XL 106 perfecting press with 18,000 sheets/hour option. This press from Heidelberger Druckmaschinen AG (Heidelberg), installed in March this year, replaces two presses in the 500 x 700mm format and meets Fabrégat's need to increase productivity and speed without compromising on quality.

As well as a new Linoprint C 751 digital printing system, the company has also invested in postpress, taking into operation a Stitchmaster ST 450 saddlestitcher in January 2014 and Stahlfolder KH 82 folding machine in July 2014.

Speedmaster XL 106 boosts productivity

Like all of the print shop's other machinery, the new Speedmaster XL 106 is equipped with the Prinect Inpress Control system for inline measurement and adjustment of ink. This saves a great deal of time and cuts waste considerably. Perfect register accuracy and consistent print quality are particularly important for production in perfecting mode at a speed of 18,000 sheets an hour. The AutoPlate XL plate changer system enables synchronised changing of all eight printing plates in a record time of 100 seconds. A Speedmaster XL 106 with this configuration is currently the best performing press on the market for both short and long runs. In the comparison between digital and offset printing, the balance is thus shifting significantly in favor of offset, as the shorter makeready times deliver considerable time savings with frequent plate changes.

The Speedmaster XL 106 impresses with its high energy efficiency and economical use of resources, making it the most environmentally friendly press in its class.

Linoprint C 751 produces backstitched brochures for very short runs with special finishing module

The Linoprint C 751 boasts outstanding register accuracy and high colour quality. JF Impression processes very short runs in no time at all without having to compromise on its own quality requirements The Linoprint C 751 boasts outstanding register accuracy and high colour quality. JF Impression processes very short runs in no time at all without having to compromise on its own quality requirements

In modernising its digital presses, Fabrégat opted for the Linoprint C 751 with a finishing module that can produce backstitched brochures. It also chose an additional multi-bypass tray for the maximum paper formats in this class 330.2 x 630mm. The Linoprint C 751 is controlled via the Prinect Digital Print Manager, which is integrated into the Prinect Prepress Manager module. This user interface, specially developed for digital systems, records all the parameters and data for digital printing. The Linoprint C 751 boasts outstanding register accuracy and high colour quality. JF Impression processes very short runs in no time at all without having to compromise on its own quality requirements.

Customer satisfaction is top priority

JF Impression is a longstanding Heidelberg customer and our partnership is based on mutual trust, explained Fabrégat. To ensure our success and the satisfaction of our customers, it's vital we always have the best performing equipment to enable us to work efficiently.

As a member of the association ImpriFrance, JF Impression holds the Imprim'Vert seal of quality and uses FSC/PEFC paper. Since 2012, it has also held ISO 12647-2 certification, which involves standardisation of internal production processes with support from Heidelberg experts. With its 44 employees in three-shift operation, JF Impression produces all kinds of print products, including in the high-end segment. Its customers, who include numerous agencies and industrial companies from a wide range of sectors, particularly appreciate the company's specialist expertise and the fast, professional results it delivers.

© Graphic Repro On-line, 1 October 2014.

|

|

|